Reducer is a kind of very precise machinery. It is an independent closed transmission device between the prime mover and the working machine. It is used to reduce the speed and increase the torque to meet the work needs. In some cases, it is also used to speed up and become a speed up engine.

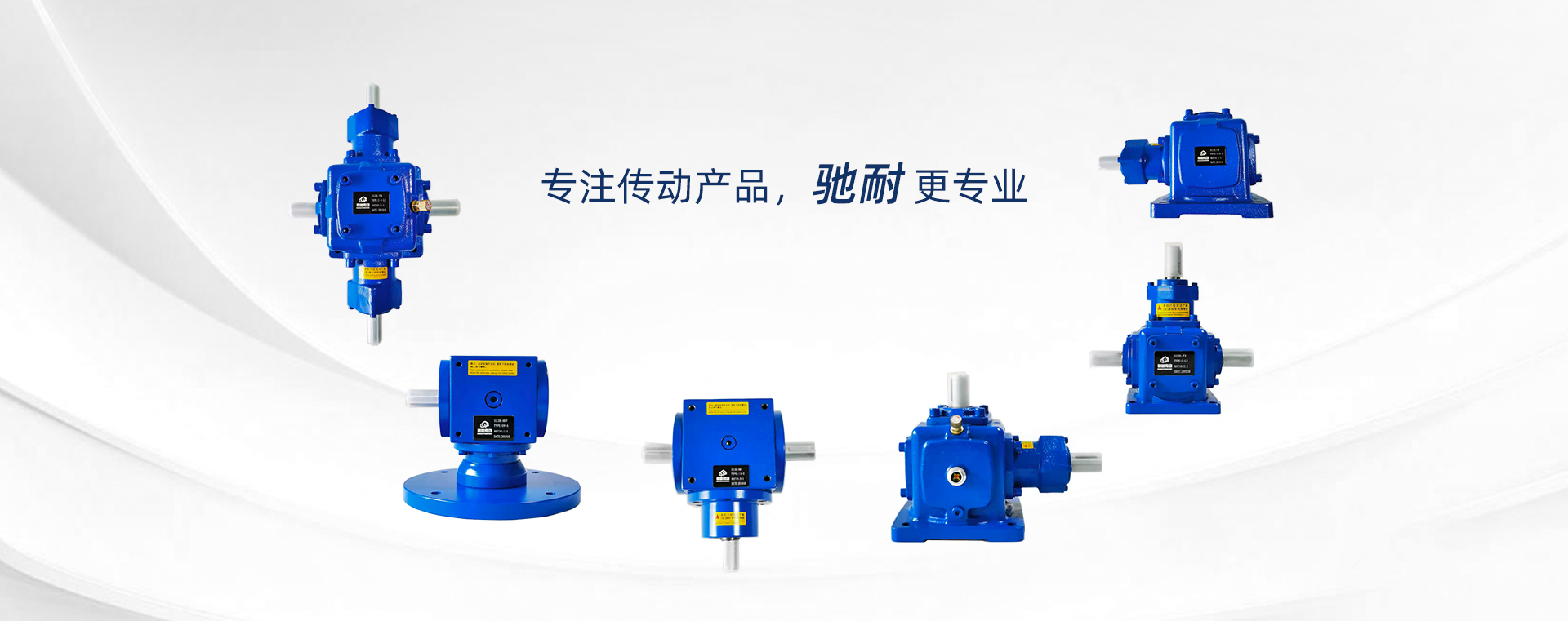

Hangzhou Chi Nai transmission machinery as a professional manufacturer of reducer for more than 10 years old enterprise, today to talk about the type of reducer and their advantages and disadvantages of application, for your reference.

Reducers can be divided into gear reducers, worm reducers, planetary reducers and their combined reducers according to transmission types. Reducers can be roughly divided into the following categories:

Worm gear reducer, planetary gear reducer, harmonic reducer, cycloid pin gear reducer, RV Reducer, three ring reducer and continuously variable transmission.

1. Characteristics of worm gear reducer

Worm gear mechanism is often used to transfer the motion and power between two staggered shafts. Worm gear and worm are equivalent to gear and rack in its middle plane, and worm is similar to screw in shape. In order to improve efficiency, non-ferrous metal is generally used as worm gear (tin bronze), and hard steel is used as worm (45 steel, 40Cr)

Advantages of worm gear reducer:

It has reverse self-locking function

Large reduction ratio

The input shaft and output shaft are not on the same axis or plane

Disadvantages of worm gear reducer:

Low transmission efficiency

The accuracy is not high

Lubricating oil is easy to leak (due to sliding friction drive, high heat will be generated during operation, resulting in difference in thermal expansion between various parts and seals of reducer, resulting in clearance on various mating surfaces, and oil becomes thinner due to temperature rise, which is easy to cause leakage)

2. Planetary gear reducer

The structure of the gear box is closely connected with an inner gear ring on the gearbox shell, and there is a sun gear driven by external power in the center of the ring gear. Between the two, there is a set of planetary gear set composed of three (or four) gears equally divided on the tray. The planetary gear set floats in the middle of the period by relying on the output shaft, the inner gear ring and the sun gear The rotation of the planet drives the output shaft connected to the tray to output power.

The main transmission structure of planetary reducer is planetary gear, sun gear and inner gear ring

Advantages of planetary gear reducer:

Small volume, light weight and high bearing capacity

Small return clearance and high precision

Stable operation, low noise and long service life

Large output torque, large speed ratio, high efficiency, safe performance and maintenance free for life

The maximum input power can reach 104kw

The minimum single-stage deceleration is 3, the maximum is generally not more than 10, and the common deceleration ratio is 3.4.5.6.8.10

Generally, the number of reducers is no more than 3, but some customized reducers with large reduction ratio have 4 reduction levels

The maximum rated input speed of planetary reducer can reach 18000rpm (related to the size of reducer, the larger the reducer, the smaller the rated input speed)

The output torque of industrial planetary reducer is generally less than 2000Nm, and that of special super large torque planetary reducer is more than 10000nm

The working temperature is generally from - 25 ℃ to 100 ℃. The working temperature can be changed by changing the grease

Most planetary reducers are installed on stepping motor and servo motor to reduce speed, improve torque and match inertia

Disadvantages of planetary gear reducer:

Because a set of planetary gears can not meet the larger transmission ratio, sometimes two or three sets are needed to meet the user's requirements for larger transmission ratio. Because the number of planetary gears is increased, the length of two or three-stage reducer will increase and the efficiency will decrease.

3. Harmonic reducer

Harmonic reducer is composed of wave generator, flexible wheel and rigid wheel, and usually adopts the form of wave generator driving, rigid wheel fixed and flexible wheel output. Generally, the rigid wheel has two more teeth than the flexible wheel. Through the so-called staggered tooth movement, the movement transmission and deceleration are realized.

Advantages of harmonic reducer:

High reduction ratio: single stage coaxial can obtain 30-320 high reduction ratio

Small backlash: different from ordinary gear meshing, the backlash is very small, which is an indispensable factor in the field of controller

High accuracy: multiple teeth are meshed at the same time, and two 180 degree symmetrical gears are meshed, so the influence of gear pitch error and cumulative pitch error on rotation accuracy is relatively average, which makes the position accuracy and rotation accuracy reach a very high level

Few parts and easy installation: the three basic parts realize high reduction ratio, and they are all on the same axis, so the installation of the kit is simple and the modeling is simple

High torque capacity: the flexspline is made of special steel with high fatigue strength. Different from the common transmission device, the number of teeth engaged at the same time accounts for about 30% of the total number of teeth, and it is face to face contact, so the pressure on each gear is reduced, and a high torque capacity can be obtained

Low noise: the meshing speed of gear teeth is low and the transmission force is balanced, so the operation is quiet and the vibration is minimal

Widely used: widely used in electronics, aerospace, robotics and other industries, due to its unique advantages, its application in the chemical industry is gradually increasing

Disadvantages of harmonic reducer:

The flexspline has limited life and is not shock resistant

The rigidity is poor compared with metal parts, and the input speed should not be too high

4. Cycloid pin gear reducer (planetary cycloid reducer)

(1) Definition: cycloid pin gear reducer is a new transmission device which applies planetary transmission principle and adopts cycloid pin gear meshing

(2) Internal structure: all the transmission devices of cycloid pin gear reducer can be divided into three parts: input part, deceleration part and output part. A 180 ° offset double eccentric sleeve is installed on the input shaft, and two roller bearings called rotating arm are installed on the eccentric sleeve to form h mechanism. The center hole of the two cycloid gears is the raceway of the arm bearing on the eccentric sleeve, and the cycloid gear is meshed with a group of ring-shaped needle teeth on the needle gear (including the needle tooth shell, the needle tooth pin and the needle tooth sleeve) to form an internal meshing reducer with tooth difference of one tooth

(3). The motion of cycloid wheel of reducer has plane motion of revolution and rotation. When the input shaft rotates forward for one cycle, the eccentric sleeve also rotates for one cycle, and the cycloid wheel rotates a tooth in the opposite direction to get deceleration. Then, with the help of W (usually the mechanism composed of output shaft, pin shaft and cycloid wheel is called w mechanism) output mechanism, the low-speed rotation motion of cycloid wheel is transmitted to the motor through the pin shaft Output shaft, so as to obtain a lower output speed

Advantages of cycloid pin gear reducer:

Power: 0.37kw ~ 55kW, torque: 150n · m ~ 20000n · M

Large reduction ratio and high efficiency: the efficiency is more than 90%, single-stage reduction ratio: 9-87, two-stage reduction ratio: 121-7569, three-stage reduction ratio: 2057-658503

Compact structure and small volume: due to the planetary transmission principle, the input shaft and output shaft are on the same axis, so that the size of the machine can be as small as possible

Reliable use and long service life: because the main parts are made of bearing steel, high strength is obtained after quenching treatment (HRC58-62), and rolling friction is used for part of the transmission contact, so they are durable and have long service life

Disadvantages of cycloid pin gear reducer:

The output shaft of cycloid pin gear reducer shall not be subjected to larger axial force and radial force, and other measures shall be taken when there is larger axial force and radial force.

The technical requirements for maintenance are higher, the bearing capacity is smaller and the price is higher than that of gears

5. RV Reducer

RV Reducer is composed of a front stage of planetary gear reducer and a rear stage of cycloid pin gear reducer. RV Reducer has compact structure, large transmission ratio and self-locking function under certain conditions. It is one of the most commonly used reducers with low vibration, low noise and low energy consumption

RV Reducer advantages:

Large transmission ratio range

The output mechanism is a planet carrier supported at both ends, which is output by the rigid big disk at the left end of the planet carrier. The big disk is connected with the working mechanism by bolts, and its torsional stiffness is much greater than that of the output mechanism of the general cycloidal pin gear planetary reducer

Under the rated torque, the elastic backlash is small; as long as the design is reasonable and the manufacturing and assembly accuracy is guaranteed, the high precision and small clearance backlash can be obtained

High transmission efficiency

6. Three ring reducer

Principle: the working principle of the basic type of three ring reducer is shown in the figure, which is composed of one low speed shaft 1 with external gear sleeve, two high speed shafts 2 with 120 degree eccentricity and three ring plates 3 with internal gear. When decelerating, the high-speed shaft 2 is used as the input shaft to drive the internal gear on the ring plate 3 to make a plane motion, and the internal gear is meshed with the gear on the low-speed shaft 1 to achieve a large speed ratio. Generally, the tooth profile is involute, and the shaft end of each input shaft can input power independently or at the same time. If increasing speed is required, shaft 1 (external gear shaft) is used as input shaft and shaft 2 as output shaft

Advantages of three ring reducer:

Large transmission ratio, single stage [i] = 11-99, two stage [i] = 50-10000

● output torque range: 0.12kn. M ≤ [t] ≤ 469kn. M

Taking advantage of the advantages of "dynamic split flow" and "multi tooth contact of internal teeth", the bearing capacity is strong

Simple structure, few parts, small volume and light weight

High efficiency, single-stage efficiency [η] = 92% - 96%

No need for special materials and special processing technology, low manufacturing cost

The linear speed of gear is low

Internal meshing mode is adopted, with multiple pairs of teeth meshing at the same time, without contact fatigue failure;

SH three ring machine can be made into horizontal, vertical and "derivative form" under various installation methods and service conditions. It can be used in all occasions where power equipment needs deceleration, especially in the environment requiring high safety factor. It is a high-grade reducer

It can be used in mining, metallurgy, petroleum, chemical industry, rubber and plastic, construction, building materials, lifting, transportation, food, light industry and other industries

The speed of high-speed shaft shall not exceed 1500r / min; the instantaneous overload torque shall not be greater than 2.7 times of the rated output torque; the working environment temperature shall be - 40 ~ 45 ℃; when it is lower than 0 ℃, the lubricating oil shall be preheated before starting, and the forward and reverse operation shall be carried out

7. Continuously variable transmission

The CVT is mainly composed of driving wheel device, friction transmission mechanism and speed control mechanism. The working radius of the friction between the planetary friction wheel and the driving wheel, the pressure plate, the fixed ring and the speed regulating cam can be changed evenly, and the stable stepless speed change can be realized

Roughly on these, such as other ideas can contact our Hangzhou Chi Nai transmission.